If you’ve ever found your home feeling too chilly and huddling under blankets during the colder months, or if your furnace has decided to take an unexpected holiday, you understand the frustration of heating issues. The furnace pressure switch allows your furnace to operate smoothly and is a gatekeeper. It only allows the furnace to fire when the air pressure is ideal. This tiny component prevents dangerous toxic gas build-up.

Unfortunately, when things go wrong, you must deal with it to prevent damage.

What is a Pressure Switch, and What does it do?

On a chilly winter evening, only to find your furnace stopped working.

What?

Yes!

In this scenario, the likely hero—or culprit—is the furnace’s pressure switch. This crucial safety device ensures the furnace ceases to operate if the venting air pressure is incorrect, effectively preventing it from running. Located near the draft inducer motor and typically round in shape, the pressure switch detects the negative pressure generated by the inducer motor as the furnace kicks on.

Since it plays a pivotal role in expelling harmful gasses like carbon monoxide and combustion fumes, it ensures they’re safely removed from your home at the start of each heating cycle.

The pressure switch’s functioning is vital; it springs into action when the inducer motor, energized by 120 volts from the control board, starts, allowing the heat exchanger to operate efficiently.

However, if the heat exchanger is faulty or a blockage occurs, the pressure switch will not close, halting the furnace’s operation. The system will attempt to restart multiple times, and if unsuccessful, the inducer motor will be powered down, and the system will shut off automatically to protect your living space. Plus, you can test the switch with a manometer if you suspect any issues. This component acts as a vigilant watchdog, safeguarding your home by monitoring the safe operational conditions of your furnace.

Common Furnace Pressure Switch Problems

Keeping this small but mighty component in check is a significant step toward a cozy, trouble-free heating season. Remember, whether your furnace is a simple single-stage model or a more complex two-stage system, the pressure switch plays a pivotal role. It’s not just about comfort—it’s about safety and efficiency, ensuring your furnace only runs when it’s safe.

Below are four common problems that occur in most furnaces.

Issue # 1: Draft Inducer Motor Failure

First of all, if there’s a problem with the draft inducer motor, the switch won’t work. This motor starts before your furnace ignites so that all harmful gases are expelled. If it fails, the pressure in your furnace won’t reach the required level to close the switch. Got the point?

Issue # 2: Obstructions in the Flue or Clogged Ports

Another issue could be a clogged port or obstruction in the flue. These ports sense pressure inside the furnace, and if they’re blocked, your furnace won’t start.

In my experience, this can be caused by anything from calcium deposits to dirt. Sometimes, even bees, wasps, or birds decide to make homes in these areas. If your furnace is not used during the off-season, a simple inspection and cleaning can clear these blockages. If you hear a flapping noise, a ruptured diaphragm inside the switch might be a common reason for failure.

Issue # 3: Stuck Diaphragm Issues

Thirdly, if your pressure switch is stuck open or closed, it might need a gentle tap on the casing to budge. However, remember, a stuck switch is a sign that it’s time for a replacement. It’s a quick fix that can save you a lot of cold nights and high repair bills down the line. Always double-check that your HVAC technician uses the proper guidelines and compatible parts for your system.

Issue # 4: Blocked Condensate Drainage

Yes.

Lastly, keep an eye on the condensate drainage. If this gets blocked, it can build up water and affect the switch. For example, if you find water in the tubing to the switch, it’s a sign that the drainage isn’t functioning correctly. Also, ensure no leaks around assemblies where air should be sealed off. Thus, ensure that all vents are unrestricted and that there’s no build-up in any part of your system.

Furnace Pressure Switch Troubleshooting – Let’s Fix Them

Once you find out the reason, it’s time to fix it without wasting time.

Step # 1: Getting Started

Before you do anything, just turn off the power and the gas. Locate the disconnect switch near the furnace; switch off the breaker in your home’s box if it’s not there. This is a must before you inspect or handle any electrical connections.

Step # 2: Inspecting the Switch & Hose

Next, open the furnace doors and check the hose(s) connected to the pressure switch. They should be firmly attached at both ends and in good condition. If you find a hose that’s cracked, frayed, or looks old, it’s best to replace it to avoid any hindrance. As you inspect these parts, you can reveal any hidden blockages or damage causing hidden furnace malfunctions.

Step # 3: Diagnosing Common Electrical Problems

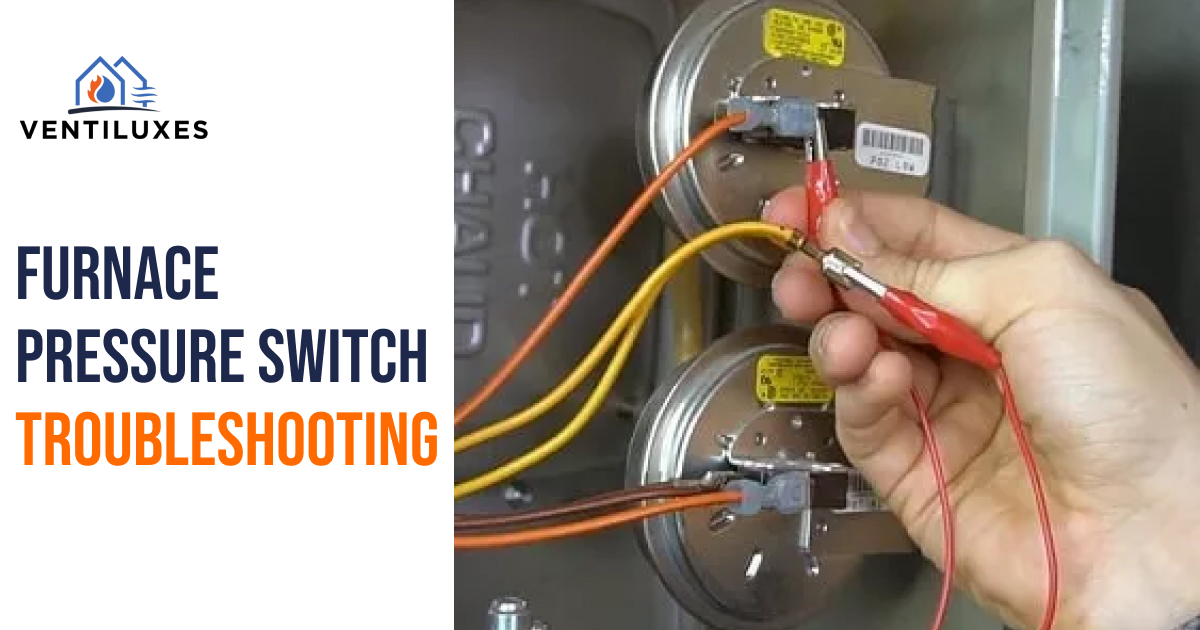

Use a multimeter to check. Please set it to measure Ohms and check for resistance at the switch terminals. If the reading is significantly higher than 0 or if there’s no continuity when the switch should be closed, this indicates a faulty switch. This simple test can save you a lot of time and trouble by pinpointing electrical issues quickly.

Step # 4: Clearing Blockages & Ensuring Proper Airflow

Always look for blockages in the vent pipes or hose port. A flashlight can help you see inside the port. If you spot any debris, carefully remove it with a small screwdriver—but be careful not to damage the pressure switch body. Clearing these blockages will fix the issue and improve the airflow within your furnace.

Step # 5: Testing and Final Checks

Once everything is clean, reconnect any loose wires and tighten connections. Reattach the furnace cover and turn the power and gas back on to test the unit.

9 Tips for Troubleshooting Your Furnace Pressure Switch

Here are some essential safety precautions to keep in mind when troubleshooting a furnace pressure switch and extending it’s lifespan :

- Power is Off: Always turn off the power to the furnace at the breaker box before beginning any work to avoid electric shock.

- Shut Off Gas Supply: Similarly, shut off the gas supply to prevent gas leaks or fire hazards while working on the furnace.

- Use Proper Tools: Employ the correct tools for the job, such as screwdrivers, flashlights, multimeters, manometer, and multimeters.

- Wear Protective Gear: Don protective eyewear and gloves to shield yourself from sharp edges and potential sparks.

- Check for Gas Leaks: After completing your work, always check for leaks before turning the gas back on. This can be done by applying a soapy water solution to the connections and watching for bubbles.

- Ventilation: Ensure the work area is well-ventilated, especially when dealing with gas appliances, to avoid inhalation of harmful gasses.

- Avoid Force: When removing or attaching parts, apply appropriate force to avoid breaking anything. If something feels stuck, review your approach instead of using more force.

- Follow Manufacturer’s Instructions: Adhere to the guidelines set by the furnace manufacturer for any specific safety measures, procedural steps, or safety standards.

- Regular Maintenance Checks: Periodically inspect your furnace and replace parts like filters and hoses as recommended to prevent emergencies.

Seek Professional Help from Ventiluxes

Hopefully, you can enjoy your furnace. If it’s still not operating correctly, it’s time to call a certified HVAC professional (Ventiluxes) to diagnose and repair more complex problems. If you are unsure or uncomfortable, don’t delay. We’re here to help you 🙂.

FAQs

What are the signs of a problem with the pressure switch?

If your pressure switch is not working right, your furnace might not start, or it might start but then stop unexpectedly.

How can you know if your furnace pressure switch isn’t working?

To check if the switch is the issue, see if the furnace fails to start or if there’s no signal reaching the furnace indicating the switch’s position.

Why would a pressure switch stop working?

A pressure switch might fail due to blockages in the tubes, problems with the wiring, or worn-out parts inside it.

What happens when a furnace pressure switch is stuck open?

If the switch is stuck open, the furnace won’t start. This is because the open switch tells the furnace is unsafe to operate.

Leave a Reply